Welcome to Mobile Biochar Systems

There are many forms of pyrolysis and not all machines are right for every application. We custom fabricate our systems to fit your needs at your site locations.

Ancient Technology for a Modern Mobile

System

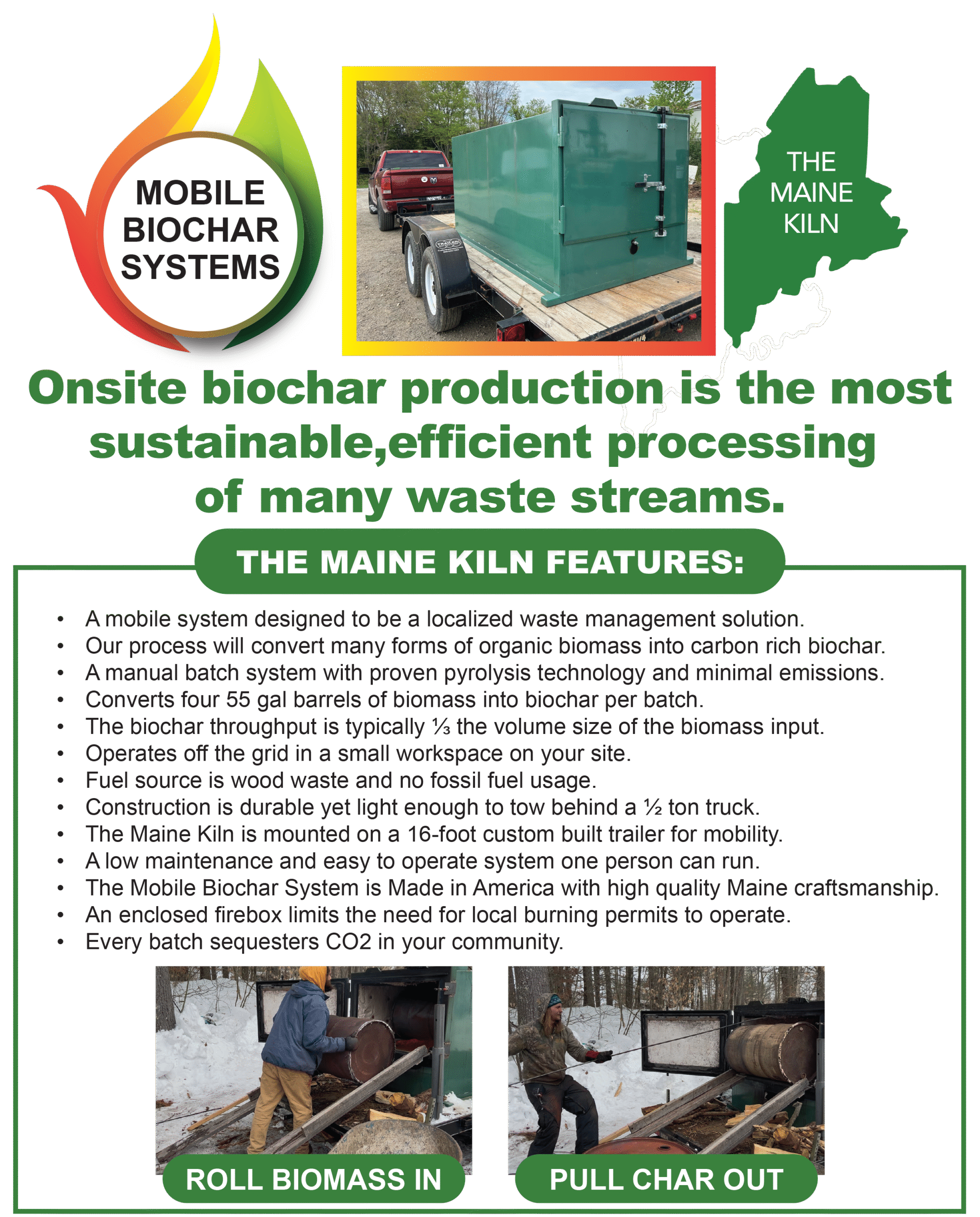

Our units are known as a retort kiln using an ancient technology called pyrolysis to produce a high quality biochar in a continuous batch system.

Durable Construction

Handcrafted in Maine with premium materials, the Maine Kiln is weatherproof, built for four-season use, and engineered to deliver long-lasting performance under the toughest heat stress conditions.

User-Friendly Operation

Mobile Biochar Systems Inc designed our machine to be a simple production unit that one person can safely operate.

Ancient Technology for a Modern Mobile

System

Our units are known as a retort kiln using an ancient technology called pyrolysis to produce a high quality biochar in a continuous batch system.

Durable Construction

Handcrafted in Maine with premium materials, the Maine Kiln is weatherproof, built for four-season use, and engineered to deliver long-lasting performance under the toughest heat stress conditions.

User-Friendly Operation

Mobile Biochar Systems Inc designed our machine to be a simple production unit that one person can safely operate.

Why the Maine Kiln

The Maine Kiln is for managing all of your organic waste streams.

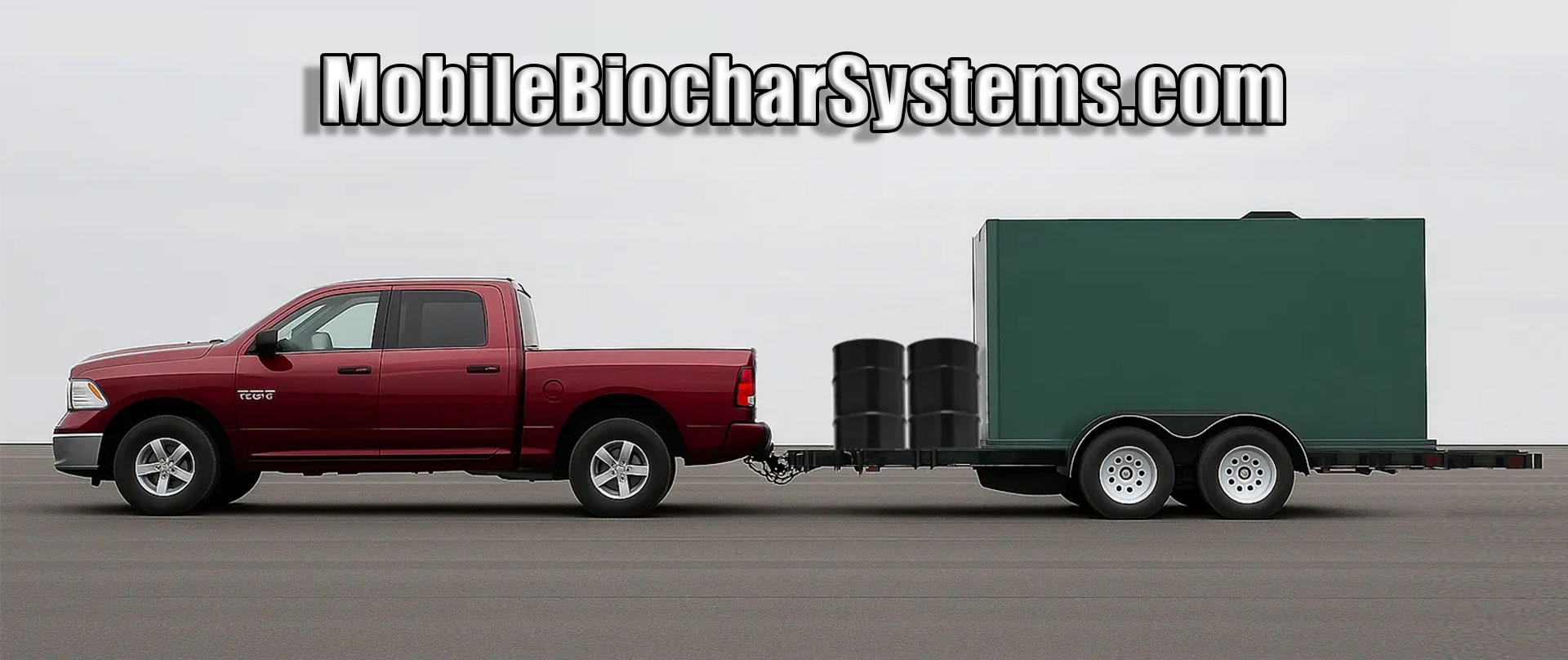

Mobility The Maine Kiln is towable by a half ton truck which goes to your feedstock efficiently processing it on site and requires no equipment to operate.

Cost benefits Paying to have your waste hauled away is costly. A Maine Kiln will eliminate disposal fees, produce biochar, a salable product with the potential to create carbon credit incomes.

Convenience No disposal scheduling, no toxic fires, no missed pick-ups and certainly no overflowing dumpsters.

QualityAs our name indicates, you’re getting a “Made in Maine” product, which means Quality is built in.

How do we capture Carbon?

Volume

The Maine Kiln reduces organic waste volumes up to 75%.

Emissions Pyrolysis airflow is designed to burn off much of the CO2, Methane and other volatile gases at a temperature between 800-1200F before exiting the flue.

Operational FuelThe Maine Kiln uses minimal wood waste to start the fire. Once up to temperature, a clean syngas is created and burned off as a renewable energy to maintain temperature with no other fuel source needed.

Carbon CaptureBiochar will sequester carbon for hundreds of years in your community.

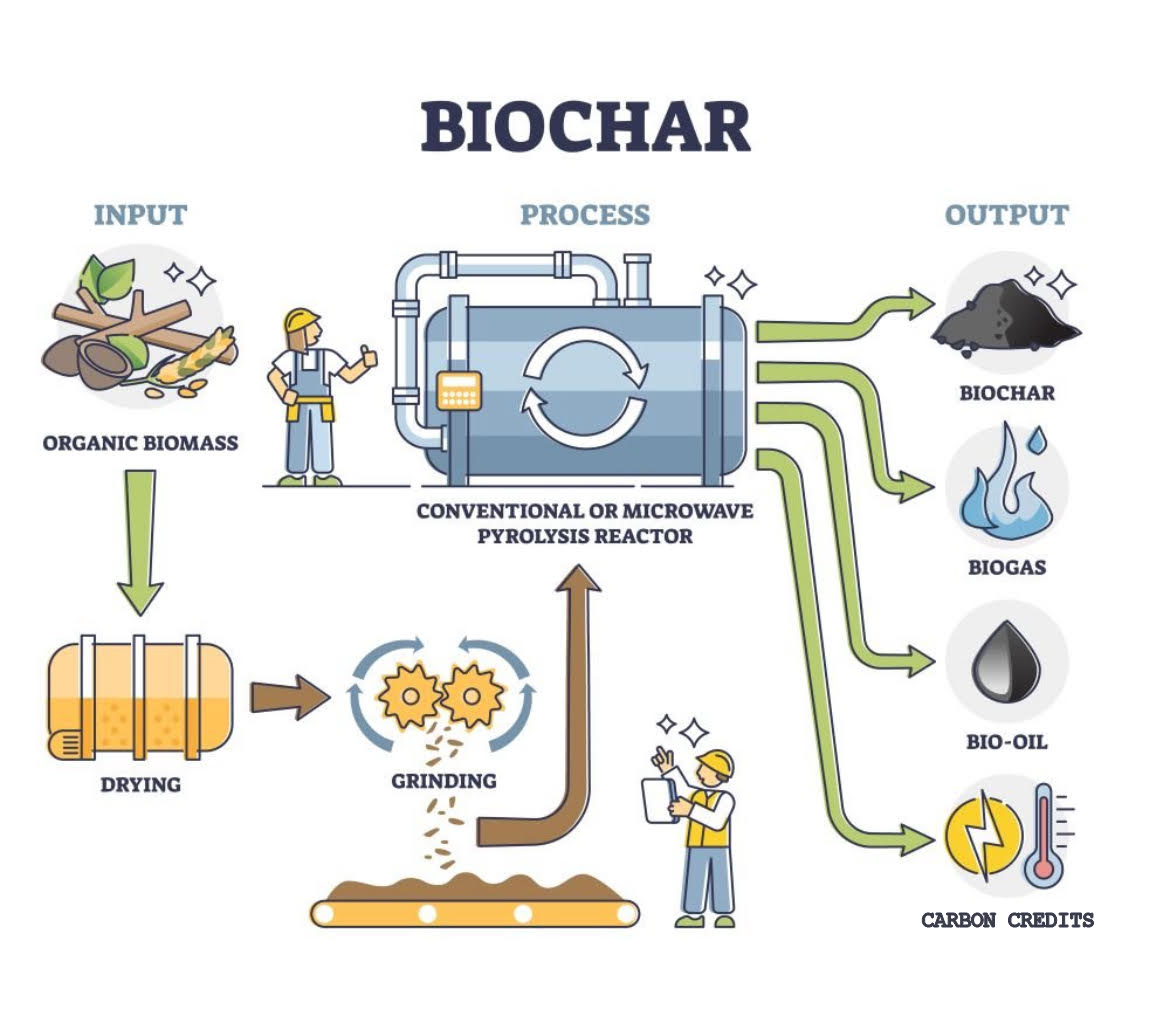

PyrolysisIs a proven carbon negative process a circular asset making a circular economy capable of producing carbon credits and creating your own circular economy with 4 byproducts for revenue stream.

What is Biochar?

Biochar is a carbon rich, charcoal-like substance, created by the thermal conversion of many forms of biomass in a low oxygen environment turning your trash into cash.

At MBS, we promote biochar as a full circle waste management solution for biomass producers of all sizes.

Small scale doesn’t have to mean small impact. Collectively an army of small biochar producers make big strides in carbon sequestration.

What we can do for you!

About Mobile Biochar Systems

Our Vision

We see biochar production as a tool for organic waste management solutions.

Cost-Effective Solutions

Innovation

Customer-Centric Support

Our team trains you hands-on, connects you with resources, and supports your success in biochar production every step of the way.

For us, customer service means being more than a vendor—we’re your partner, connector, and educator. We share knowledge openly, support your success, and help strengthen the entire biochar industry.

Our Biochar Story

Waste is not waste until you waste it.

Our mobile systems bring biochar technology to your site, eliminating hauling and unlocking sustainable waste solutions anywhere.

In 2019, founder Kevin Bernard set out to solve a growing problem: mountains of cannabis biomass heading for the dumpster every day. His search for a sustainable solution led him to biochar—and the realization that waste management needed to be cleaner, smarter, and mobile.

The first experiments were rough: a makeshift kiln welded together from an oil tank and two used barrels. But failure sparked innovation. Kevin built a mobile four-barrel prototype, proving that biochar technology didn’t have to be tied to a single site—it could move to where the waste is.

After two years of testing, redesigning, and refining, that concept evolved into the Maine Kiln, a rugged second-generation system engineered for efficiency and reliability. Alongside key partners like Growthcraft and the Just Co-op who mentored scaling efforts, we fine-tuned performance and burn quality, pushing mobile biochar technology forward.

In 2025, we rebranded as Mobile Biochar Systems, Inc. to say exactly what we do: design and build mobile kilns that bring biochar production to your site. No hauling waste. No waiting. No wasted energy.

Today, our systems are in the field, delivering real results—and scaling fast. Because the future of waste management isn’t stationary. It’s mobile.

Call, email or stop by!